Assalamu alaikum, nine editan.Akwai nau'ikan masu haɗin lantarki da yawa, gami da haɗin btb, amma tsarin masana'anta iri ɗaya ne, gabaɗaya zuwa matakai huɗu masu zuwa:

1. Tambari

Tsarin ƙera na'urorin haɗin lantarki gabaɗaya yana farawa da fil masu tambari.Ta hanyar babban na'ura mai saurin naushi, mai haɗin lantarki (pin) yana naushi daga siraran ƙarfe.Ƙarshen babban bel ɗin ƙarfe mai naɗe yana aika zuwa ƙarshen gaban na'urar, ɗayan kuma za a wuce ta na'urar aikin hydraulic na na'urar don a raunata a cikin keken reling, sa'an nan kuma za a ciro bel ɗin karfe ta hanyar bel ɗin. reling wheel da ƙãre samfurin aka birgima fita.

2. Electroplating

Ya kamata a aika fil masu haɗawa zuwa sashin lantarki bayan an gama yin hatimi.A wannan mataki, za a yi amfani da fuskar wutar lantarki na mai haɗawa tare da nau'i-nau'i na karfe daban-daban.Matsalolin da ke kama da mataki na stamping, kamar karkatarwa, guntu ko nakasar fil, kuma za su bayyana lokacin da aka ciyar da fil ɗin da aka hati a cikin kayan aikin lantarki.Ta hanyar dabarun da aka bayyana a cikin wannan labarin, ana iya gano irin wannan lahani mai inganci cikin sauƙi.

Duk da haka, ga yawancin masu samar da tsarin hangen nesa na inji, yawancin lahani masu inganci a cikin tsarin lantarki har yanzu suna cikin "yankin da aka haramta" na tsarin dubawa.Masu kera masu haɗa kayan lantarki suna fatan tsarin dubawa zai iya gano lahani iri-iri iri-iri da ba su dace ba kamar ƙananan tarkace da ramuka a saman platin fil ɗin haɗin.Ko da yake waɗannan lahani suna da sauƙin ganewa don wasu samfurori (kamar aluminum na iya kasa ko wasu shimfidar wuri mai faɗi);duk da haka, saboda tsarin shimfidar wuri mara tsari da kusurwa na mafi yawan masu haɗin lantarki, tsarin dubawa na gani yana da wahala a samu Hoton da ake buƙata don gano waɗannan lahani.

Saboda wasu nau'ikan fil suna buƙatar a sanya su tare da nau'ikan ƙarfe masu yawa, masana'antun kuma suna fatan cewa tsarin ganowa zai iya bambanta nau'ikan suturar ƙarfe daban-daban don tabbatar da ko suna cikin wurin kuma adadin daidai yake.Wannan aiki ne mai wuyar gaske ga tsarin hangen nesa da ke amfani da kyamarori baki da fari, saboda matakan launin toka na hotuna na suturar ƙarfe daban-daban kusan iri ɗaya ne.Kodayake kamara na tsarin hangen nesa na launi na iya samun nasarar bambanta waɗannan nau'ikan suturar ƙarfe daban-daban, matsalar hasken haske mai wuya har yanzu yana wanzu saboda kusurwar da ba ta dace ba da kuma nuna yanayin rufin.

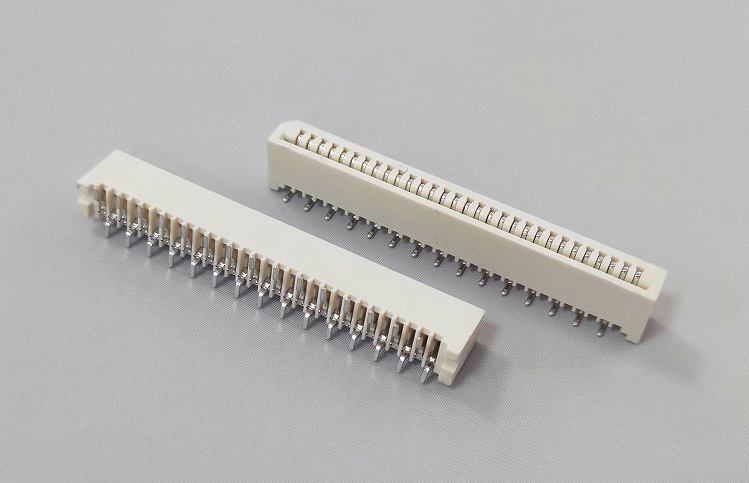

YFC10L SERIES FFC/FPC MAI HADA MAI HADA:1.0MM(.039″) TSAYE NA SMD BA-ZIF

3. Allura

Akwatin akwatin filastik na mai haɗin lantarki an yi shi a cikin matakin gyaran allura.Tsarin da aka saba shine a yi allurar robobi na narkakkar a cikin fim ɗin ƙarfe na tayin, sannan a kwantar da shi da sauri ya zama.Lokacin da narkakkar robobin ta kasa cika kwata-kwata kwata-kwata, abin da ake kira "leak?"(Short Shots) yana faruwa, wanda shine nakasu na yau da kullun da ake buƙatar ganowa a matakin gyaran allura.Sauran lahani sun haɗa da cikawa ko toshe ɓangaren soket (waɗannan Socket ɗin dole ne a kiyaye su da tsabta kuma a buɗe su don a iya haɗa shi daidai da fil yayin taron ƙarshe).Domin amfani da hasken baya yana iya gano wurin zama na akwatin da ya ɓace cikin sauƙi da kuma toshewar soket, ana amfani da shi don hangen nesa na na'ura don dubawa mai inganci bayan gyare-gyaren allura.Tsarin yana da sauƙi mai sauƙi kuma mai sauƙin aiwatarwa

4. Majalisa

Mataki na ƙarshe na masana'anta mai haɗin lantarki ya ƙare taron samfur.Akwai hanyoyi guda biyu don haɗa fil ɗin lantarki zuwa wurin zamar akwatin allura: ɗaiɗaikun mating ko haɗuwa da juna.Mating na dabam yana nufin saka fil ɗaya a lokaci ɗaya;hade mating yana nufin haɗa fil da yawa tare da wurin zama a lokaci guda.Ko da wane irin hanyar haɗin da aka karɓa, masana'anta na buƙatar cewa an gwada duk fil ɗin don ɓacewa da matsayi daidai yayin matakin taro;wani nau'in aikin dubawa na al'ada yana da alaƙa da ma'aunin nisa tsakanin saman mating na mai haɗawa.

Kamar matakin stamping, haɗin haɗin haɗin kuma yana haifar da ƙalubale ga tsarin dubawa ta atomatik dangane da saurin dubawa.Kodayake yawancin layukan taro suna da guda ɗaya ko biyu a cikin daƙiƙa guda, tsarin hangen nesa yawanci yana buƙatar kammala abubuwa daban-daban na dubawa don kowane mai haɗawa da ke wucewa ta cikin kyamara.Sabili da haka, saurin ganowa ya sake zama muhimmin ma'aunin aikin tsarin.

Bayan an gama taron, ma'aunin waje na mahaɗin sun fi girma da izinin juriyar juzu'i na fil ɗaya a cikin tsari na girma.Wannan kuma yana kawo wata matsala ga tsarin dubawa na gani.Misali: wasu kujerun akwatunan haɗin haɗin suna da girman ƙafa ɗaya kuma suna da ɗaruruwan fil, kuma daidaiton kowane matsayi na fil dole ne ya kasance cikin 'yan dubbai na inci.Babu shakka, ba za a iya gano mai haɗin kafa ɗaya mai tsayi akan hoto ba, kuma tsarin dubawa na gani zai iya gano iyakacin ƙimar fil a cikin ƙaramin filin gani a lokaci guda.Akwai hanyoyi guda biyu don kammala binciken duk mai haɗawa: ta yin amfani da kyamarori masu yawa (ƙara farashin tsarin);ko ci gaba da haifar da kamara lokacin da mai haɗawa ya wuce gaban ruwan tabarau, kuma tsarin hangen nesa ya “stitches” da ci gaba da kama hotuna guda ɗaya , Don yin hukunci ko ingancin duk mai haɗawa ya cancanta.Hanya ta ƙarshe ita ce hanyar dubawa da tsarin dubawa na gani na PPT ke ɗauka bayan an haɗa mai haɗin.

Lokacin aikawa: Satumba 24-2020