Electroplating crystallization process

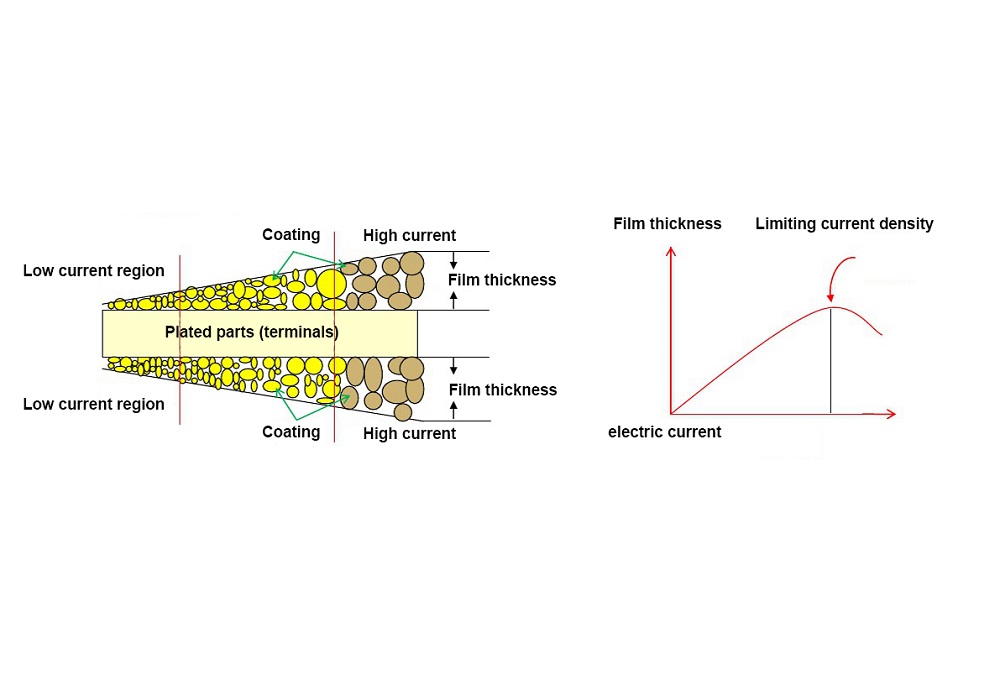

1.Under certain conditions, the higher the current is, the thicker the coating film is, the single current reaches a certain limit, and the film layer blasphemy will not increase with the current increasing.

2. Under the same conditions, the higher the current, the larger the electroplating crystal particles, the larger the pinhole degree, and the poor corrosion resistance.

3.In the limit current electroplating, the coating not only crystal particles, and the arrangement of crystal particles irregular, luster, SEM bad condition, LLCR,BAKE test have an impact

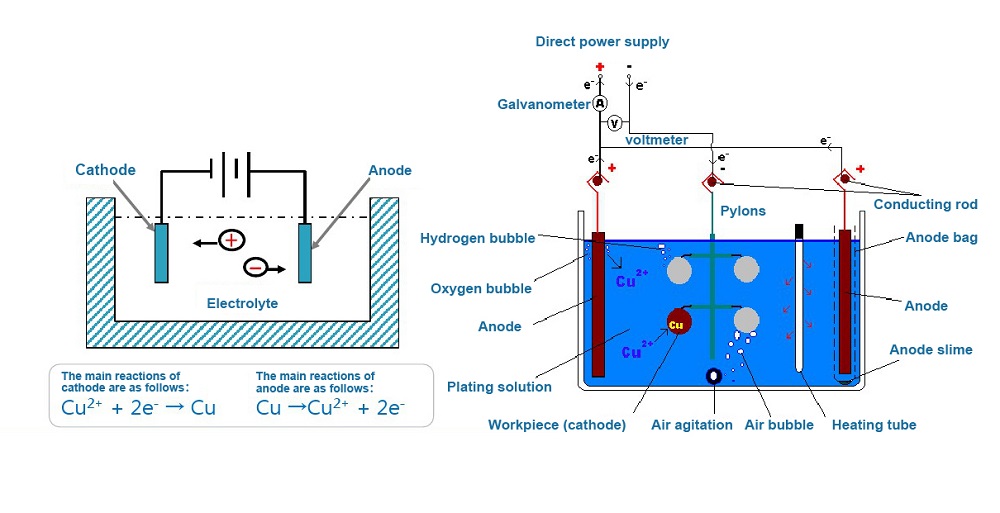

the anode and cathode of the DC power supply are connected to the cathode of the aqueduct, the anion in the electroplating solution loses electrons for oxidation reaction at the anode, and the cation gains electrons for reduction reaction at the cathode.

Electroplating process

When electroplating, the metal pieces as the cathode, the gold plated or alloy as the anode, respectively connected in a good conductive electrode, and immersed in electrolytic solution containing coating components, and then through direct current.

Three elements of electroplating

Dc power supply

The electrode of Yin and Yang

Electrolyte containing ions intended for gold plating

Post time: Jul-22-2020