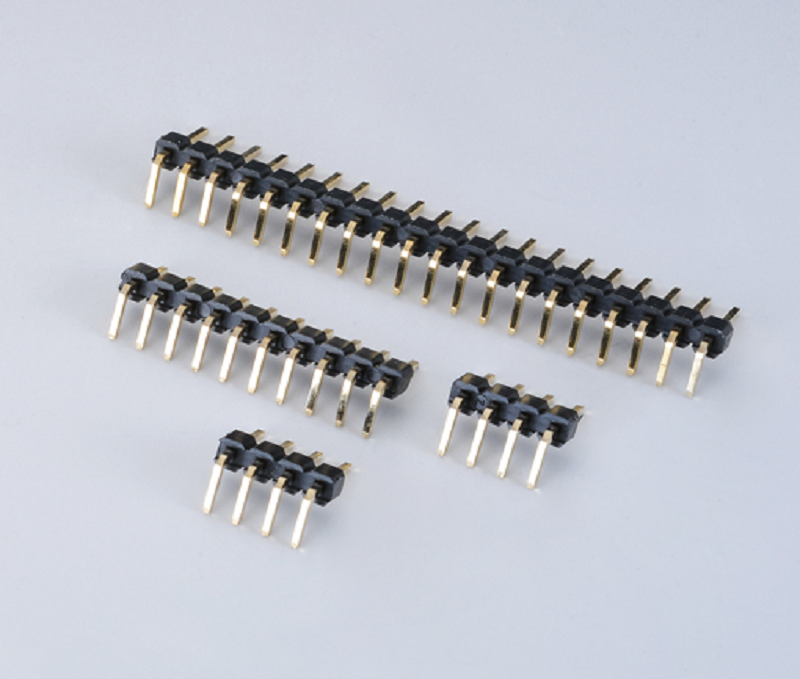

Assalamu alaikum, nine editan.Abu ɗaya yana buƙatar amfani da haɗin haɗi don haɗawa da wani abu.Saboda haka, akwai masu haɗin jirgi da yawa a kusa da mu, kuma kowa ya san shi sosai.A yau, editan zai zo ya koyi tare da ku waɗanne halaye na fasaha masu haɗin allo-da-board, kamar haka:

1. Da farko, "laushi", haɗin kai mai sauƙi, sauƙi don shigarwa da sauƙi don rarrabawa.

2. Matsakaicin ƙarancin tsayin mai haɗa allo zuwa allo don cimma manufar rage kaurin jiki.

3. Tsarin lamba yana da juriya na muhalli.Ba wai kawai mai sauƙi ba ne, amma kuma yana amfani da "haɗi mai ƙarfi" tare da babban amintaccen lamba don inganta ƙarfin haɗin gwiwa na soket da filogi.Yana da sauƙi don amfani da ƙayyadaddun sassa na ƙarfe da kuma sassan sadarwa.Tsarin kullewa, yayin haɓaka ƙarfin haɗin gwiwa, yana sanya shi ƙarin toshewa da cirewa lokacin kullewa

4. Domin saduwa da bukatun na SMT tsari, da m waldi yankin na dukan samfurin ne tsananin da ake bukata don samun mai kyau coplanarity.

5. A matsananci-kunkuntar hukumar-zuwa-board connector sa gaba sabon buƙatun ga electroplating tsari.Yadda za a tabbatar da cewa samfurin ta zinariya plating kauri da tinning sakamako ba su hawa tin, ya zama matsananci-key matsala a connector miniaturization.

6. Za'a iya gina mai haɗin jirgi-da-board don ƙirar ƙirar injin mai sauƙi.Ta hanyar samar da bango mai rufewa a saman ƙasa na mai haɗawa, za a iya karkatar da alamar hukumar PCB da tashar ƙarfe da kuma yin waya a saman ƙasan mai haɗin ba tare da lamba ba, wanda ke da fa'ida sosai ga miniaturization na hukumar PCB.

7. Haɗa jagorar tsari.Tare da ci gaban zamani, ana samun ƙarin aikace-aikace na masu haɗin haɗin micro.Don haka, lokacin haɗuwa, dole ne ku daidaita kusurwar gabatarwa sannan kuma danna shi ƙasa da ƙarfi don guje wa lalacewar samfur ta lalacewa da latsawa.

Lokacin aikawa: Oktoba-21-2020