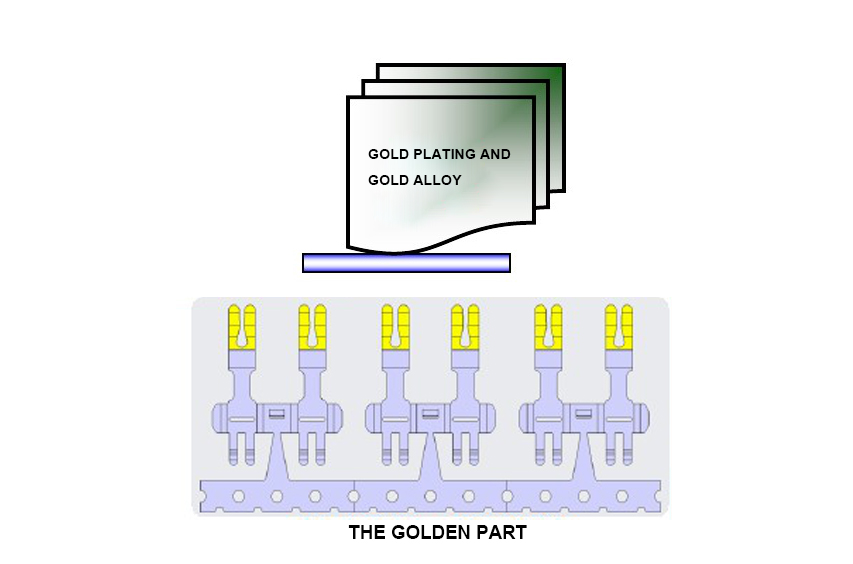

Ukuqaliswa kokufakwa kwegolide

I-1.Igolide yintsimbi yegolide exabisekileyo ethambileyo kwaye kulula ukuyipolisha.

I-2.Igolide inozinzo olulungileyo lwekhemikhali, olunganyibilikiyo kwi-asidi eqhelekileyo, i-soluble kuphela kwi-aqua regia.

I-3.I-Gold i-coating inokumelana ne-corrosion eyomeleleyo kunye nokuchasana okulungileyo kwi-discoloration

4.Ukufakwa kwegolide kunemibala eyahlukeneyo, ekwasetyenziselwa iingubo zokuhombisa ezibizayo

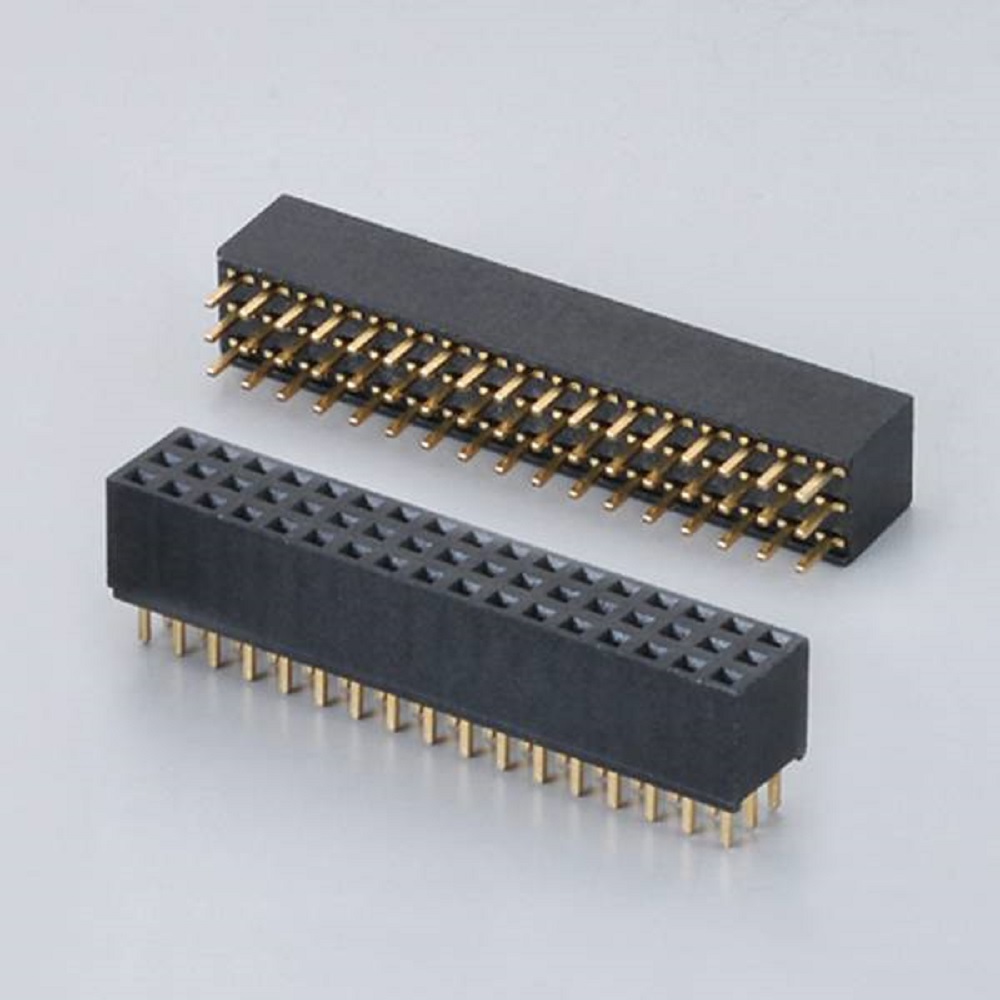

I-PITCH YE-HEADER YOMFAZI:2.0MM(.047″) UROW OTHATHU OKUQONDILE 180°

I-5.Gold ine-contact ephantsi yokuchasana kunye ne-conductivity enhle, kwaye idla ngokusetyenziswa kwiimeko zokudibanisa i-sliding.

I-6.I-Gold plating ilula ukuwelda kwaye inokumelana nobushushu obuhle,ukusebenza okuthile okuxhathisayo, kodwa qaphela, ayikho igolide eshinyeneyo elula ngakumbi ukuwelda, ngokuchaseneyo, ubukhulu bomaleko wegolide 3-5 ų ° isiphumo sokuwelda. yeyona ilungileyo.

I-7.Ukongezwa kobhedu kwigolide kunempembelelo encinci kubunzima, kodwa ukongezwa kwe-nickel ye-10% kunempembelelo enkulu kubunzima.Ngaphandle koko, i-au-NI alloy inozinzo oluphezulu.

8.Ukuxinana komoya okungalunganga kwegolide, igolide esezantsi iya kuba ne-diffusion phenomenon. Ngokubanzi ngesiseko se-nickel, shiya ukuthintela ukusasazwa komzantsi wegolide.

I-9.Igolide inendawo ephantsi yokunyibilika kwaye inyibilika ngokulula kwi-tin ngexesha le-nickel welding, okukhokelela ekubunjweni kweekhompawundi ze-AU-SN kunye nokwakhiwa kwe-brittleness yegolide.

10. Amandla okuthintela ukubola kwengxubevange yobhedu eyi-original efakwa kwi-nickel ų 50 ° ilungile kakhulu, kodwa okoko nje kwi-nickel - ukubethelela umaleko wesicatshulwa, isakhono sokumelana nokubola sibi kakhulu. Isizathu kukuba umahluko onokubakho phakathi kwegolide kunye i-nickel inkulu kakhulu, nto leyo ebangela ukusabela kokutya okukhawulezileyo kweGalliani.Umfuniselo wokutshiza ityuwa ungqina ukuba le nkcazo-bungcali ichanekile.Ekuqaleni, i-nickel ngaphandle kokutyalwa kwegolide ecekethekileyo ingahlala iiyure ezingama-72, ngelixa inickel enegolide encinci ayinakuhlala iiyure ezingama-48.

Ukuqaliswa kwe-tin electroplating

1.I-Tin inenkangeleko esilivere-mhlophe.

I-2.I-Tin ayinyangeki ku-corrosion, imelana nombala, ayinayo ityhefu, kulula ukuweld kunye ne-ductile

I-3.I-Tin yokugquma inozinzo oluphezulu lweekhemikhali

4.I-electrical conductivity ye-tin yokugquma ilungile, kulula ukuyidibanisa, kwaye ihlala isendaweni yetoti yesilivere.

5.kwi-coating ine-fenomenon ye-tin fever, kodwa hayi nge-bismuth, i-antimony alloy\

I-6.I-Tin yokugqoka kwiqondo lokushisa eliphezulu, imanzi, iimeko ezivaliweyo ziya kuvelisa i-whiskers.

I-7.Indawo yokunyibilika ye-tin-lead alloy iphantsi kunelothe ecocekileyo kunye ne-tin ecocekileyo, i-porosity yayo kunye ne-weldability ingcono kunentsimbi enye, kwi-tin ecocekileyo nje ngokuba ukongezwa kwe-2-3% lead, akulula ukuyenza. ukuvelisa iwhisker yenkcenkce, ngoko ke ukutyabeka kwe-tin-lead yealloy yeyona nto ibalulekileyo yokwaleka ethengiswa kumacandelo e-elektroniki, inokungena endaweni yokwaleka kwesilivere kuluhlu oluthile.

I-8.Ihlala isetyenziselwa izinto zokuwelda kwaye ingasetyenziselwa ukugquma amandla amakhulu oqhagamshelwano.

Ixesha lokuposa: Jul-22-2020