Nhanganyaya yegoridhe plating

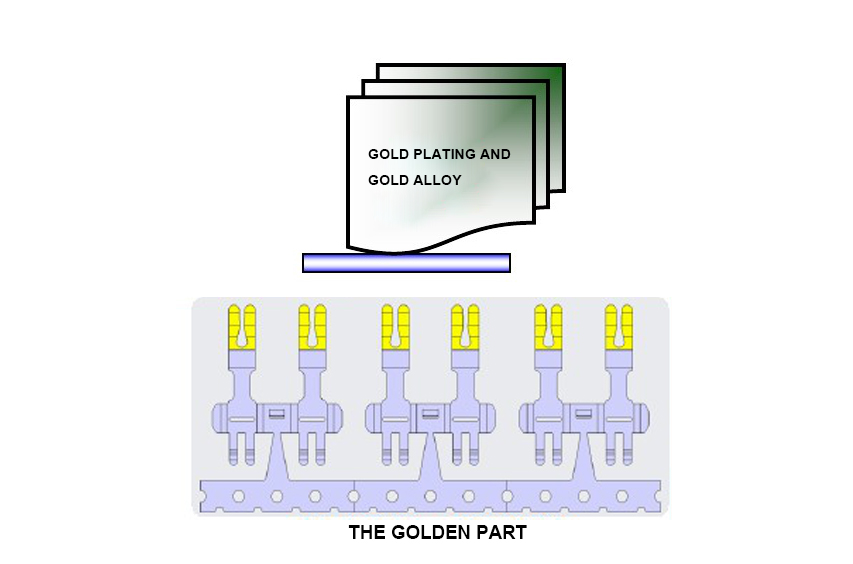

1.Gold isimbi yakakosha yegoridhe inogadzika uye iri nyore kukwenenzvera.

2.Goridhe ine kugadzikana kwakanaka kwemakemikari, isinganyungudika mumaasidhi akajairwa, inonyungudika chete muaqua regia.

3.Gold coating ine yakasimba corrosion resistance and good resistance to discoloration

4.Kuiswa kwegoridhe kune mavara akasiyana-siyana, inoshandiswawo kune zvinodhura zvekushongedza zvipfeko

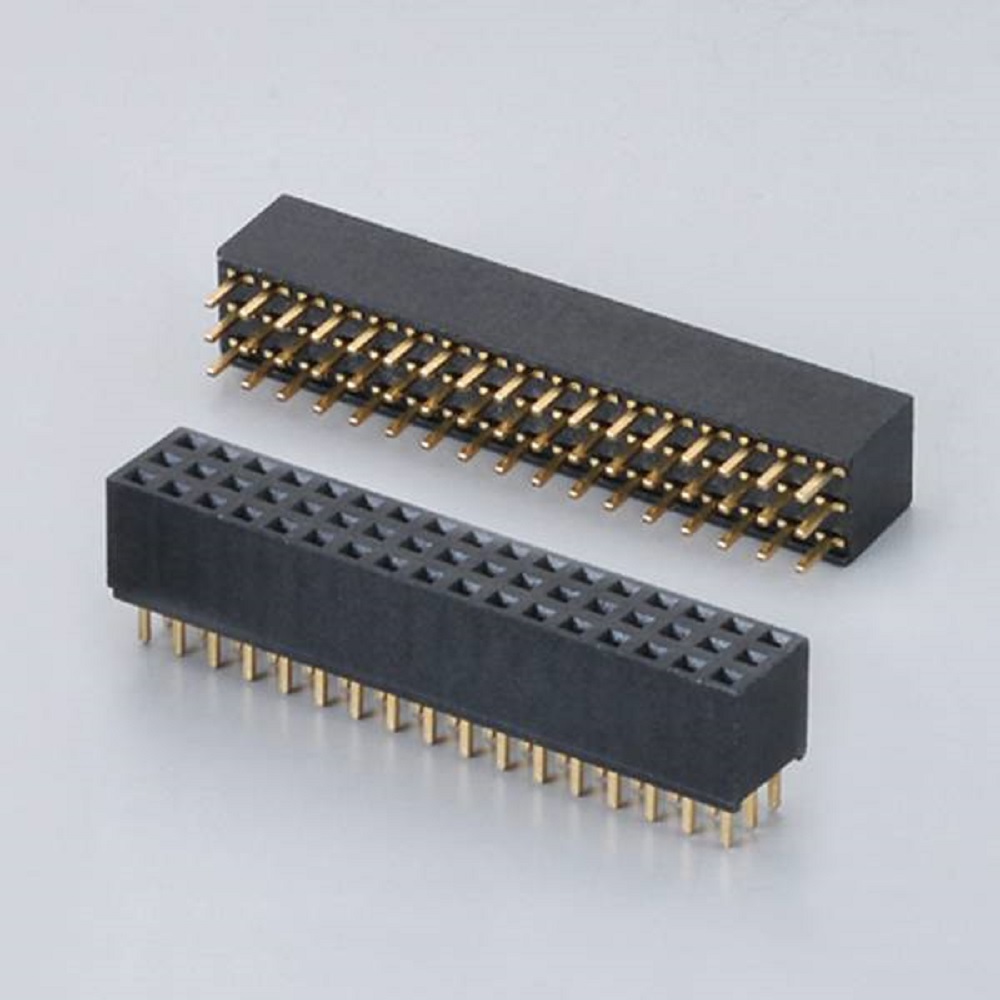

MUSORO WECHIkadzi:2.0MM(.047″) TRIPLE ROW STRAIGHT 180°

5.Gold ine low contact resistance uye yakanaka conductivity, uye inowanzoshandiswa mukutsvedza kusangana nemamiriro.

6.Gold plating iri nyore kune welding uye ine yakanaka tembiricha kuramba, zvimwe kupfeka-kupokana kuita, asi chenjerera, haisi gobvu goridhe zviri nyore kuputika, pane zvinopesana, ukobvu hwegoridhe rakaturikidzana 3-5 ų ° welding effect. ndizvo zvakanakisisa.

7.Kuwedzerwa kwemhangura kune goridhe kune zvishoma zvishoma pakuoma, asi kuwedzera kwe10% nickel kune simba guru pakuoma.Kunze kwezvo, au-NI alloy ine yakanyanya kugadzikana.

8.Kusasimba kwemweya wegoridhe, goridhe repasi rinenge riine diffusion phenomenon.Kazhinji nenickel base, siya kudzivirira kupararira kwegoridhe pasi.

9.Gold ine nzvimbo yakaderera yekunyungudika uye inonyungudika nyore mutin panguva ye nickel welding, zvichikonzera kuumbwa kweAU-SN compounds uye kugadzirwa kwegoridhe brittleness.

10. Anticorrosive kugona yepakutanga mhangura alloy plating pamusoro nickel ų 50 ° yakanaka chaizvo, asi chero bedzi nickel - plating runyoro rwechinyorwa, ngura inodzivirira kugona kwakashata kwazvo. Chikonzero ndechekuti musiyano uripo pakati pegoridhe ne nickel yakakura kwazvo, izvo zvinokonzeresa kukurumidza kuita ngura kweGalliani.Kuedza kwemunyu kunoratidza kuti dzidziso iyi ndeyechokwadi.Pakutanga, nickel isina kutetepa goridhe yakanamirwa inogona kugara maawa makumi manomwe nemaviri, nepo nickel ine goridhe yakatetepa plating haigone kugara maawa makumi mana nemasere.

Nhanganyaya yetin electroplating

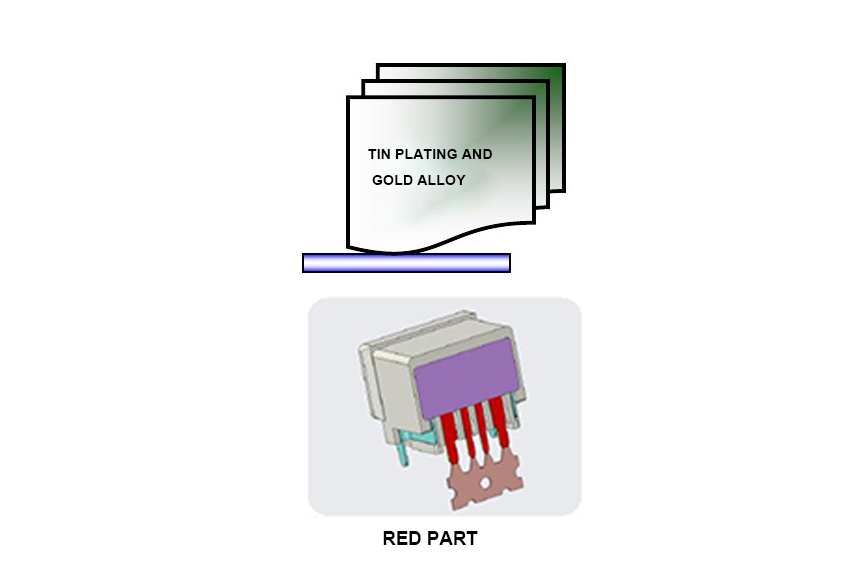

1.Tin ine chitarisiko chesirivha-chena.

2.Tin inodzivirirwa necorrosion, inodzivirira ruvara, haina chepfu, iri nyore kupinza uye ductile.

3.Tin coating ine yakakwirira kugadzikana kwemakemikari

4.Electrical conductivity yetin coating yakanaka, nyore kupinza, uye kazhinji panzvimbo yesimbi yesirivha.

5.Mukupfeka zvine chiitiko chetin fever, asi kwete nebismuth, antimony alloy\

6.Tin coating pakupisa kwepamusoro, kunyorova, kuvharwa kunoburitsa ndebvu dzemarata.

7.Kunyunguduka kwetin-lead alloy yakaderera pane pure lead uye tin yakachena, porosity yayo uye weldability iri nani kupfuura simbi imwe chete, mune yakachena tini chero bedzi kuwedzera kwe 2-3% mutungamiri, hazvisi nyore gadzira tin whisker, saka tin-lead alloy coating ndiyo yakakosha solderable coating muzvikamu zvemagetsi, inogona kutsiva iyo sirivheri mukati meimwe siyana.

8.Iyo Inowanzo shandiswa kune welding zvinhu uye inogonawo kushandiswa kune yakakura yakanaka simba rekubata coating.

Nguva yekutumira: Jul-22-2020